4 Major Types of Bricks for Cement Kilns

Views: 0 Author: Site Editor Publish Time: 2025-10-24 Origin: Site

Cement kilns endure temperatures exceeding 1,500°C, demanding materials that can withstand extreme conditions. Refractory bricks play a crucial role in maintaining kiln efficiency and longevity. In this article, we will explore the four major types of refractory bricks used in cement kilns: fire clay bricks, high alumina bricks, silica bricks, and magnesia bricks. Each type offers unique benefits tailored to specific kiln zones, ensuring optimal performance.

The Role of Refractory Bricks in Cement Kilns

Why Refractory Bricks Are Crucial for Cement Kilns

Refractory bricks play a crucial role in the operation of cement kilns. They are engineered to handle extreme conditions, such as high temperatures, mechanical wear, and chemical corrosion. Without high-quality refractory bricks, the cement kiln would not be able to maintain its temperature, operate efficiently, or last long enough for proper cement production. Refractory bricks line the kiln shell, ensuring that heat is retained inside the kiln, reducing energy consumption and preventing the kiln from deteriorating.

Key Factors to Consider When Selecting Refractory Bricks

Selecting the right type of refractory brick depends on several factors:

Temperature Resistance: Different areas of the kiln experience different temperatures. The brick must be able to handle the maximum temperature encountered in each zone.

Chemical Resistance: The kiln is exposed to various chemicals, including alkaline and acidic compounds. The brick must be resistant to these elements.

Mechanical Strength: Bricks must be able to withstand the mechanical stresses that come with the kiln's rotation and the thermal shock it undergoes.

Choosing durable bricks reduces the frequency of replacements and the associated costs.

Fire Clay Bricks: A Reliable Solution for Moderate Temperatures

Composition and Characteristics of Fire Clay Bricks

Fire clay bricks, also known as refractory fire bricks, are made from high-grade fireclay. They are known for their excellent thermal stability and ability to resist abrasion under moderate heat. Typically, fire clay bricks can withstand temperatures up to 1,300°C, making them ideal for areas of the cement kiln that do not experience extreme heat.

Best Applications of Fire Clay Bricks in Cement Kilns

These bricks are commonly used in the lower preheating zones of the kiln, where temperatures are not as high as the burning zone. Fire clay bricks are suitable for areas where moderate heat and some abrasion occur but where resistance to high temperatures or chemicals is not as critical.

Pros and Cons of Fire Clay Bricks

Pros:

Cost-effective

Reliable for moderate temperature areas

Good thermal resistance

Cons:

Not suitable for high-temperature zones

Can degrade quickly if exposed to high thermal shock

When looking for a cost-effective solution for moderate temperature zones, fire clay bricks provide reliable performance and value.

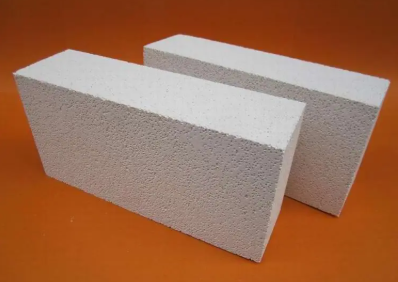

High Alumina Bricks: Superior Performance in High-Temperature Zones

Key Features of High Alumina Bricks

High alumina bricks contain a higher percentage of alumina (Al2O3), typically around 40-85%. This higher alumina content gives these bricks superior thermal shock resistance and excellent resistance to chemical erosion. They can withstand higher temperatures than fire clay bricks, often up to 1,800°C, making them ideal for the hottest parts of the cement kiln.

Where to Use High Alumina Bricks in Cement Kilns

These bricks are best suited for the transition and burning zones of the cement kiln. In these zones, they encounter intense heat and chemical reactions, and they need to maintain structural integrity and resist erosion. High alumina bricks help in achieving a more durable and efficient kiln.

Benefits and Drawbacks of High Alumina Bricks

Benefits:

Excellent resistance to high temperatures and thermal shock

High mechanical strength

Chemical resistance to acidic and alkaline environments

Drawbacks:

More expensive than fire clay bricks

May require specialized installation due to their higher hardness

For kilns operating at high temperatures, high alumina bricks are a great choice due to their superior thermal resistance and longer lifespan.

Silica Bricks: Exceptional Resistance to Acidic Conditions

What Makes Silica Bricks Special for Cement Kilns?

Silica bricks are made primarily from silicon dioxide (SiO2), which gives them exceptional resistance to acidic environments and high-temperature conditions. These bricks can withstand temperatures up to 1,800°C, making them suitable for areas exposed to acidic slags and other aggressive materials.

Ideal Applications for Silica Bricks

Silica bricks are typically used in the upper preheating zones of the kiln and in cyclone preheaters. These areas experience high temperatures but are also subjected to acidic chemical reactions. Silica bricks provide reliable performance and help prevent damage from acidic slags.

Advantages and Limitations of Silica Bricks

Advantages:

Excellent resistance to acidic corrosion

High-temperature stability

Suitable for the upper preheating zone and other acidic environments

Limitations:

Susceptible to thermal shock

May not perform well under alkaline conditions

For cement kilns dealing with high levels of acidic slags or corrosive environments, silica bricks are an excellent option to protect your kiln lining.

Magnesia Bricks: Optimal for Alkaline Environments

What Are Magnesia Bricks Made of?

Magnesia bricks are made from magnesium oxide (MgO), which provides exceptional resistance to basic slags and high-temperature alkaline environments. These bricks can withstand temperatures of up to 2,000°C, making them ideal for the most extreme parts of the cement kiln, including the burning zone and cooler.

Applications of Magnesia Bricks in Cement Kilns

Magnesia bricks are commonly used in the burning zones and coolers of cement kilns. In these areas, they endure high temperatures and are exposed to alkaline materials, which they resist effectively. Their superior thermal shock resistance and durability make them essential for these critical areas of the kiln.

The Pros and Cons of Magnesia Bricks

Pros:

High resistance to basic slags and alkaline environments

Can withstand extreme temperatures up to 2,000°C

Excellent durability and thermal shock resistance

Cons:

Expensive compared to other refractory bricks

May require specialized handling and installation

Magnesia bricks are the go-to choice for areas of the cement kiln exposed to extreme temperatures and alkaline conditions, providing unmatched durability.

Choosing the Right Refractory Brick for Your Cement Kiln

Factors to Consider When Selecting Refractory Bricks

Selecting the right refractory brick depends on a variety of factors:

Temperature gradients: The area of the kiln will experience different temperatures.

Chemical exposure: The kiln's environment may contain alkaline or acidic substances that affect the bricks.

Mechanical stress: Some areas of the kiln experience more wear and tear than others.

Lifespan and durability: High-performance bricks generally cost more but last longer.

The Importance of Compatibility with Kiln Operating Conditions

It's essential to choose a refractory brick that matches the operating conditions of the kiln. For example, if the kiln operates at higher temperatures, high alumina or magnesia bricks may be required. On the other hand, if the kiln is exposed to more acidic conditions, silica bricks may offer the best performance.

Expert Tips on Making the Best Choice

Evaluate kiln conditions: Understand the temperature, chemical exposure, and mechanical stress in each zone of the kiln.

Consult with suppliers: Work with a trusted refractory manufacturer to select the right materials for your specific kiln.

Focus on durability: Invest in high-quality bricks that offer better longevity, even if they come at a higher initial cost.

Conclusion

Selecting the right type of Refractory Brick for cement kilns is critical to ensuring the kiln's performance, longevity, and energy efficiency. Fire clay, high alumina, silica, and magnesia bricks each offer unique advantages depending on the specific zone and conditions of the kiln. By carefully considering factors such as temperature, chemical exposure, and mechanical stress, you can choose the most suitable refractory brick for your needs. Don't forget to consult with a reliable refractory supplier, such as ZIBO ZHUOYUE REFRACTORY CO., LTD, to ensure your kiln runs smoothly and efficiently for years to come.

FAQ

Q: What are the 4 major types of refractory bricks for cement kilns?

A: The four major types are fire clay bricks, high alumina bricks, silica bricks, and magnesia bricks. Each type is suitable for different kiln zones based on temperature and chemical exposure.

Q: What is the role of refractory bricks in cement kilns?

A: Refractory bricks protect the kiln from extreme temperatures and chemical damage, ensuring efficient and safe operation. They help in maintaining heat and improving energy efficiency.

Q: How do I choose the right refractory brick for my cement kiln?

A: Consider factors such as temperature, mechanical stress, and chemical exposure. For high temperatures, high alumina or magnesia bricks are ideal, while fire clay bricks suit moderate conditions.

Product Category

zbzy@hotmail.com