Step-by-Step Process of Making High-Quality Refractory Bricks

Views: 0 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

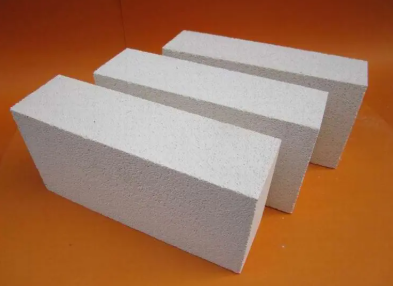

Refractory bricks are vital for industries exposed to extreme heat. Have you ever wondered how these durable bricks are made? In this article, we will explore the step-by-step process of manufacturing refractory bricks. You'll learn how raw materials are transformed into bricks that withstand high temperatures and their role in various industries.

Refractory bricks are designed to endure high temperatures, making them indispensable for industries that handle extreme heat. The process of manufacturing these bricks involves several steps that ensure their strength, durability, and resistance to thermal shock. Understanding how to make refractory bricks is essential for businesses in industries such as steel and cement, where these materials are critical for efficient operations.

Understanding the Raw Materials for Refractory Bricks

Types of Raw Materials Used

The primary raw materials used in the production of refractory bricks include high-alumina bauxite, silica, magnesite, and corundum. These materials are carefully selected based on their ability to withstand high temperatures and their chemical properties.

High-alumina bauxite is used for making high-alumina bricks.

Silica is primarily used to produce silica bricks, known for their high thermal stability.

Magnesite and corundum are used in the production of bricks that can handle extreme heat and corrosion.

Sourcing and Quality Control

The raw materials are sourced from various suppliers and must meet strict quality standards. Before entering the production process, each batch is inspected to ensure it meets the required specifications. Only high-purity materials are selected to ensure the durability and performance of the final product.

The Importance of Purity in Raw Materials

The purity of the raw materials directly influences the performance of the refractory bricks. Impurities can weaken the structure of the brick, affecting its ability to resist high temperatures and thermal shock. Therefore, manufacturers pay close attention to the quality of each ingredient.

Always ensure that your supplier provides certified, high-quality raw materials to avoid issues with the final product's performance.

The Step-by-Step Process of Making Refractory Bricks

Crushing, Grinding, and Sizing

The raw materials are first crushed and ground to the desired particle size. The size distribution is crucial for achieving a high packing density, which directly impacts the final brick's strength. Coarse aggregates are mixed with finer powders to ensure uniform consistency and performance.

Mixing and Batching

Once the raw materials are properly sized, they are weighed and mixed in specific proportions according to the formula. Water is carefully added to the mixture, as the right moisture content is essential for proper shaping and to avoid cracks during drying. The materials are then mixed in large industrial mixers to ensure even distribution of all components.

Shaping and Forming

The mixed materials are shaped into bricks using one of several methods:

Semi-dry pressing is the most common technique, where a pressure of 50-150 MPa is applied to form the bricks.

Plastic forming is used for clay-rich mixtures that have a higher moisture content.

Isostatic pressing applies uniform pressure from all directions, resulting in dense, strong bricks.

Vibration forming or casting is used for specialized bricks or monolithic products.

The method of shaping determines the brick's density, porosity, and mechanical strength.

Drying and Firing

Before the bricks can be fired in a kiln, they must be dried to remove any excess moisture. This step is critical to prevent cracking during the firing process. The drying temperature typically ranges between 110-150 °C. Once dried, the bricks are ready for the high-temperature firing process.

Firing and Curing

Firing is done in kilns at temperatures between 1300-1800 °C, depending on the material type. For example, clay bricks are fired at approximately 1350 °C, while high-alumina bricks require higher temperatures, up to 1600 °C. During firing, the bricks undergo sintering, where their particles bond together, creating a strong, durable final product. The firing process must be closely monitored to ensure the bricks reach the correct temperature without over- or under-firing.

Quality Control and Testing of Refractory Bricks

Key Quality Parameters

Quality testing is essential to ensure that refractory bricks meet industry standards. Key properties tested include:

Bulk density: Ensures the brick is compact and strong.

Apparent porosity: Affects the brick's ability to withstand thermal shock.

Cold crushing strength: Measures the brick's resistance to pressure.

Refractoriness under load (RUL): Indicates how the brick performs under high-temperature stress.

Ensuring Consistency and Reliability

Quality control is performed throughout the manufacturing process. Regular testing ensures that each batch of bricks meets the necessary specifications for use in demanding industrial applications.

Always request a certificate of quality from your supplier to guarantee that the refractory bricks meet your required standards.

Grading and Classification

Refractory bricks are classified based on their properties and performance. Different industries require specific types of bricks, such as high-strength dense bricks for steel manufacturing or lightweight insulating firebricks for energy-efficient applications.

Forming Refractory Bricks: Techniques and Equipment

Semi-Dry Pressing vs. Plastic Forming

Semi-dry pressing and plastic forming are two of the most widely used shaping methods in refractory brick production. Semi-dry pressing is an excellent technique for producing dense and strong bricks. It involves applying high pressure, usually between 50 to 150 MPa, which compacts the materials into a solid structure. This process is ideal for producing bricks that must withstand extreme heat and pressure. On the other hand, plastic forming is used for mixtures that have higher moisture content, making the brick more flexible. This technique is commonly used for bricks that require detailed molding or those used in applications where a higher level of plasticity is needed to handle stresses.

Advanced Techniques: Isostatic Pressing

Isostatic pressing is an advanced shaping technique that applies uniform pressure to the material from all directions. This method is commonly used for creating high-density, premium-grade refractory bricks. The uniform pressure ensures that the materials are compacted evenly, resulting in bricks that have superior mechanical strength and resistance to thermal shock. Isostatic pressing is especially useful for high-performance applications that demand exceptional durability and reliability. The choice of forming method—whether semi-dry pressing, plastic forming, or isostatic pressing—depends on the specific requirements of the final application, such as the type of furnace or kiln it will be used in.

Automation in the Shaping Process

Automation has become a critical component in the modern refractory brick manufacturing process. Automated machinery ensures consistent brick size and quality, which significantly reduces human error and increases production efficiency. Automation allows for precise control over the mixing, forming, and shaping stages, ensuring uniformity in the final product. Additionally, automated systems can work continuously, increasing output while reducing labor costs. Automation also helps maintain consistent quality across large production runs, ensuring that each brick meets the stringent specifications required by industries such as steel, glass, and cement manufacturing.

The Role of Drying and Firing in Refractory Brick Quality

Importance of Drying Before Firing

Drying is a crucial step in the manufacturing of refractory bricks. It ensures that the bricks do not crack or warp during the high-temperature firing process. During drying, free moisture is gradually removed from the bricks at controlled temperatures, typically between 110-150°C, to prevent uneven drying, which could result in structural failure. Proper drying allows for a uniform moisture content throughout the brick, ensuring that it will not absorb excess moisture during the firing process, which can lead to cracks and surface imperfections. It is essential to monitor the moisture levels to avoid problems that could impact the final quality and performance of the bricks.

The Firing Process and Temperature Curves

Firing is the most critical stage in the production of refractory bricks, as it influences the final properties of the material. The temperature curve during the firing process must be carefully controlled to ensure the bricks reach the optimal sintering temperature without exceeding it. Sintering is the process where particles bond together to form a strong and durable brick, and achieving the right temperature is essential for creating a brick that can withstand extreme conditions. If the temperature is too high, the bricks can become too brittle, while too low a temperature may result in incomplete sintering, weakening the brick's structure.

The Effect of Firing on Brick Properties

The firing process plays a significant role in determining the final microstructure of the refractory brick. During sintering, heat causes the raw materials to bond together at the microscopic level, creating a brick with improved strength, density, and resistance to high temperatures. The properties of the brick, such as its ability to withstand thermal shock and pressure, are directly influenced by the firing temperature and duration. As the temperature increases, the internal structure of the brick becomes more compact, which enhances its ability to resist cracking and wear under high heat. Proper firing ensures that the brick is durable and performs reliably in demanding industrial environments.

Refractory Brick Applications Across Industries

Steel and Metal Industry

Refractory bricks are indispensable in the steel and metal industries, where they are used in a wide range of applications, including blast furnaces, electric arc furnaces, and converters. These bricks provide critical insulation and protection for equipment exposed to extremely high temperatures, preventing heat loss and protecting metal structures from the corrosive effects of molten metal. Refractory bricks are designed to withstand constant thermal cycling and pressure, making them essential for maintaining efficient and safe operations in steel production. They also help improve energy efficiency by minimizing heat loss in high-temperature furnaces.

Glass Manufacturing

In glass production, refractory bricks are used in applications such as melting tanks and regenerators. These bricks are exposed to high temperatures and often corrosive environments, where they provide insulation and protect the furnace walls from damage. Refractory bricks play a key role in maintaining the integrity of the furnace, ensuring that it can withstand the harsh conditions of continuous glass melting. The bricks also help to maintain a stable temperature within the furnace, which is crucial for consistent glass quality and production efficiency.

Cement Production

In cement manufacturing, refractory bricks are used to line the interiors of rotary kilns and pre-calciners, where temperatures can reach up to 2000°C. These bricks ensure that the furnace walls remain intact under extreme conditions, protecting the kiln's structural integrity while allowing it to operate at peak efficiency. The refractory bricks used in cement production are designed to resist thermal shock, high abrasion, and chemical corrosion from the raw materials, ensuring long-term durability and minimizing maintenance requirements.

Ceramics and Non-Ferrous Metals

Refractory bricks also find applications in the ceramics industry, where they are used in kilns for firing ceramic products at high temperatures. Additionally, these bricks are employed in aluminum and copper smelting processes, where they protect the furnace from intense heat and prevent metal corrosion. The durability and thermal resistance of refractory bricks make them essential for maintaining the stability of high-temperature equipment used in non-ferrous metal production.

Packaging, Delivery and Final Considerations

Packaging and Protection During Transport

Refractory bricks are highly durable, but they still require careful packaging during transportation to avoid damage. High-value products are typically individually boxed and protected with cushioning materials to prevent cracks, chips, or other forms of physical damage during transit. Refractory bricks must be handled with care to ensure that they reach their destination in the same condition as when they left the manufacturing facility, especially for specialized bricks that are used in critical applications.

Handling High-Value Products

Premium refractory bricks, especially those used in high-performance applications, require extra care during handling and transport. Because these bricks are often used in industries where performance is crucial, ensuring that they arrive without damage is of utmost importance. Additional protective measures may be taken, such as using wooden crates, securing the bricks with straps, or adding extra padding to prevent shifting during transportation.

Final Testing and Certifications

Before shipment, refractory bricks undergo thorough testing to ensure they meet the required performance specifications. These tests evaluate key properties such as strength, porosity, and thermal resistance to ensure that the bricks can withstand the high temperatures and stresses they will face in industrial applications. Each shipment is accompanied by inspection certificates that guarantee the quality and authenticity of the products. It is essential for buyers to verify that their refractory bricks are accompanied by these certificates to ensure that they meet the necessary standards for their intended use.

Conclusion

The process of making Refractory Brick is intricate, requiring precision in raw materials, shaping, firing, and quality control. By understanding this process, businesses can select the best materials for high-temperature applications. With the right manufacturing techniques and thorough testing, refractory bricks deliver dependable performance in challenging industrial conditions. For high-quality refractory solutions, ZIBO ZHUOYUE REFRACTORY CO.,LTD offers products designed to meet these exacting standards.

FAQ

Q: What is a Refractory Brick?

A: A refractory brick is a heat-resistant material used to line furnaces, kilns, and reactors. It can withstand high temperatures and chemical corrosion, making it ideal for industries like steel, cement, and glass.

Q: How are Refractory Bricks made?

A: The making of refractory bricks involves selecting raw materials, mixing, forming, drying, and firing at high temperatures. Each step in the making refractory bricks process ensures durability and heat resistance.

Q: Why are Refractory Bricks important for high-temperature industries?

A: Refractory bricks protect equipment from extreme heat and chemical damage. They provide insulation and ensure efficient, safe operation in industries such as steel, cement, and glass production.

Product Category

zbzy@hotmail.com